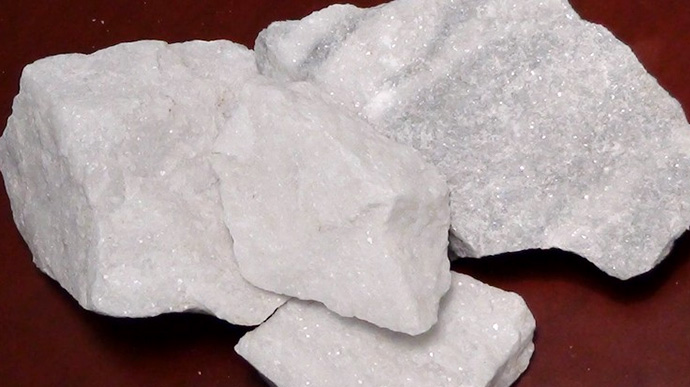

Dolomite, a versatile calcium-magnesium carbonate mineral, is widely used in construction, ceramics, glass, and environmental protection industries. To meet global demand for high-quality dolomite powder, Liming Heavy Industry offers advanced crushing and processing solutions tailored for efficient production and cost optimization.

Dolomite Crushing Process

The crushing stage is critical for reducing large dolomite blocks to manageable sizes. Liming’s jaw crushers and impact crushers ensure reliable primary and secondary crushing. For example, the PEW series jaw crusher handles initial size reduction (150-900 mm), while the PF series impact crusher achieves fine (15-50 mm) with minimal wear. These machines feature robust structures and adjustable discharge ports, adapting to diverse feed materials.

Dolomite Grinding & Classification

After crushing, dolomite undergoes grinding to achieve desired fineness. Liming’s MTW European-style trapezoidal mill and TGM series super-pressure trapezoidal mill are ideal for ultra-fine grinding (D97 ≤ 5 μm). These mills integrate drying, grinding, and classification, reducing energy consumption by 30% compared to traditional systems. The closed-circuit design ensures uniform particle distribution, with particles recycled for re-grinding.

Why Choose Liming?

30+ Years of Expertise: Customized solutions for non-metallic mineral processing.

Energy Efficiency: Low power consumption and durable components.

Global Support: Professional engineers provide technical guidance and after-sales service.

Customer Success

A client in China’s construction sector reported a 50% increase in production efficiency after adopting Liming’s mobile crusher, meeting demands for 100 km of downstream markets.

Liming Heavy Industry’s dolomite crushing and grinding systems combine innovation and reliability, ensuring high-quality output and operational cost savings. For tailored solutions, contact Liming’s team to unlock the full potential of your dolomite resources.