PE Jaw Crusher

The jaw crusher, also known as the jaw breaker or jaw crushing machine, commonly referred to as the “tiger mouth” or “jaw crusher,” holds a dominant position among crushing equipment. It is primarily used for various ores and large chunks of material, leading the charge in crushing production lines for coarse and medium crushing operations. It boasts advantages such as stable operation, high crushing ratio, environmental friendliness, low energy consumption, and long service life. Consequently, its application range has expanded, and its fields have extended from sole mining to numerous sectors including construction materials, highways, railways, water conservancy, and chemical industry.

Working Principle of PE Jaw Crusher

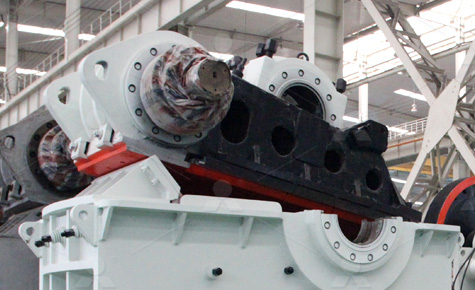

The jaw crusher machine is mainly composed of a frame, a supporting device, a working mechanism (fixed jaw plate and movable jaw plate), a transmission mechanism (eccentric connecting rod, thrust plate, flywheel, eccentric shaft), a safety device, and an adjustment device for the discharge port (wedge adjustment device, gasket adjustment device).

The jaw crusher machine is mainly composed of a frame, a supporting device, a working mechanism (fixed jaw plate and movable jaw plate), a transmission mechanism (eccentric connecting rod, thrust plate, flywheel, eccentric shaft), a safety device, and an adjustment device for the discharge port (wedge adjustment device, gasket adjustment device).

The motor drives the belt and pulley to move the movable jaw up and down through the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw increases, thereby pushing the movable jaw plate to approach the fixed jaw plate. At the same time, the material is crushed or split to achieve the purpose of crushing; when the movable jaw descends, the angle between the toggle plate and the movable jaw decreases. Under the action of the pull rod and spring, the movable jaw plate leaves the fixed jaw plate. At this time, the crushed material is discharged from the lower port of the crushing chamber. With the continuous rotation of the motor and the periodic movement of the movable jaw of the crusher, the material is crushed and discharged, realizing batch production.

When manufacturing equipment, LIMING manufacturers use wear-resistant high manganese steel for the movable jaw liner and fixed jaw liner, cast babbitt alloy for the main bearing liner and eccentric bearing liner, and cast iron for the toggle plate to improve its durability and reduce downtime.

PE Jaw Crusher Details

Specifications - Technical Data

| Model | Feed opening (mm) | Max. Feeding Size (mm) | Adjustable Discharge opening (mm) | Capacity (t/h) | Motor Power (kW) | Overall Dimensions (mm) | Weight (t) |

| PE250×400 | 250X400 | 200 | 20-60 | 5-20 | 15(20) | 1150×1275×1240 | 2.8 |

| PE250x1000 | 250X1000 | 210 | 15-50 | 15-50 | 30(40) | 2790x2670x1380 | 6.5 |

| PE400×600 | 400X600 | 350 | 40-100 | 15-60 | 30(40) | 1700×1732×1653 | 6.5 |

| PE500×750 | 500X750 | 425 | 50-100 | 50-100 | 55(75) | 2035×1921×2000 | 10.3 |

| PE600×900 | 600X900 | 500 | 65-160 | 60-130 | 75(100) | 2290×2206×2370 | 16 |

| PE750×1060 | 750X1060 | 630 | 80-140 | 110-250 | 110(150) | 2620×2302×3110 | 27 |

| PE900×1200 | 900X1200 | 750 | 100-200 | 160-380 | 130(175) | 3789×2826×3025 | 46.5 |

| PE1000×1200 | 1000X1200 | 850 | 200-300 | 315-550 | 130(175) | 3889×2826×3025 | 56 |

| PE1200×1500 | 1200X1500 | 1000 | 150-350 | 400-800 | 200(270) | 4930X3148X3560 | 88 |