Mobile Primary Jaw Crusher

From single machine running to multiterminal online application, Mobile Primary Jaw Crusher can satisfy customers’ diversified demand.

Working Principle

The equipment integrates the jaw crusher mainframe, power system, and feeding and screening unit through modular design, taking into account efficient crushing and mobility, significantly reducing material transportation costs and improving operating efficiency

1. Integrated feeding and pre-screening

The material is evenly transported to the jaw crushing chamber through the vehicle-mounted feeder. Some models are equipped with a vibrating screen to pre-separate fine particles to reduce ineffective crushing.

2. Moving jaw extrusion crushing

The motor drives the eccentric shaft to rotate, driving the moving jaw plate to periodically approach and move away from the fixed jaw plate. When the moving jaw moves upward, the distance between the two jaw plates is reduced, and the material is crushed by squeezing and rolling; when the moving jaw moves downward, the distance is expanded, and the crushed material is discharged from the discharge port under the action of gravity.

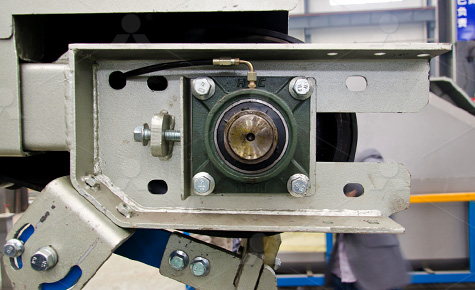

3. Hydraulic adjustment and overload protection

The size of the discharge port is adjusted in real time through the hydraulic system (such as the toggle plate back seat or wedge adjustment device) to control the finished product particle size (usually 1-300mm). When encountering unbreakable objects or overload, the hydraulic device automatically relieves pressure to avoid equipment damage.

4. Closed-loop circulation and finished product transportation

The crushed materials are directly output through the on-board belt conveyor, or returned to the screening system for closed-loop circulation to ensure that the particle size meets the standard. The mobile station integrates a vibrating screen and a conveyor belt to achieve continuous operation of “on-site crushing-screening-transfer”.

5. Mobile migration and rapid transfer

Using tire or crawler chassis, no fixed foundation installation is required, and it can be flexibly transferred with the advancement of the mining face or the needs of the construction site, especially suitable for mobile scenes such as construction waste treatment and mining.

Details

Specifications - Technical Data

| Model | Feeding Equipment | Crushing Equipment | Max. preparedness capacity(t/h) | Overall Dimension | Weight (t) | ||

| Model | Model | Max. Feeding Size(mm) | output

(t/h) |

Transport dimension (need tear-down) | |||

| KE600-1 | TSW0936 | PE600×900Ⅱ | 500 | 90-180 | 100-210 | 12150×2600×3950(mm) | 43 |

| KE750-1 | TSW1139 | PE750×1060 | 630 | 110-300 | 130-330 | 13000×2850×4400mm | 61 |

| KE760-1 | TSW1139 | PEW760 | 640 | 150-310 | 170-330 | 13000×2800×4200(mm) | 55 |

| KE860-1 | TSW1345 | PEW860 | 720 | 200-420 | 230-450 | 14600×3000×4500(mm) | 64 |

| KE1100-1 | TSW1548 | PEW1100 | 930 | 300-600 | 350-650 | 14050×2900×4000(mm) | 96 |

| KF1214Ⅱ-1 | TSW0936 | PFW1214Ⅱ | 500 | 110-190 | 120-210 | 12150×2600×3980(mm) | 48 |

| KF1214Ⅱ-1 | TSW1139 | PFW1214Ⅱ | 500 | 110-190 | 140-230 | 13000×2800×4200(mm) | 53 |

| KF1315Ⅱ-1 | TSW1345 | PFW1315Ⅱ | 600 | 180-280 | 190-310 | 14600×3100×4500(mm) | 61 |

| KF1415Ⅱ-1 | TSW1548 | PFW1415Ⅱ | 700 | 280-450 | 310-480 | 14050×3000×4000(mm) | 74 |